Factory Cheap Hot Self-Hardening Furan Resin - Sulfonic Acid Curing Agent for Self-hardening Furan Resin – Crownchem

Factory Cheap Hot Self-Hardening Furan Resin - Sulfonic Acid Curing Agent for Self-hardening Furan Resin – Crownchem Detail:

Packaging and Storage

Sealed packaging in plastic drums, net weight 25kg or 1000kg. Please store in a ventilated and cool place, avoid direct sunlight, and prohibit open flames.

It is strictly forbidden to directly mix with resin to avoid explosion accidents.

Please wear labor protection equipment when using it. If come into direct contact with your body, please immediately wash it with clean water and receive medical treatment if necessary.

Specifications / Model

| MODEL | Density

g/cm3 |

Viscosity

mpa.s≤ |

Acidity in sulfuric acid % | Free sulfuric acid %≤ | Applicable sand temperature range℃ | Applicable scope |

| RHG-04 | 1.10-1.15 | 10-15 | 25 | 4-6 | 25–30 | Gray Ductile Iron Casting |

| RHG-03 | 1.15-1.18 | 15-18 | 30 | 6-8 | 20-25 | Gray Ductile Iron Casting |

| RHG-O9 | 1.16-1.20 | 16-20 | 35 | 8-9 | 15-20 | Gray Ductile Iron Casting |

| RHG-10 | 1.25-1.30 | 20-25 | 40 | 9-11 | 0-10 | Gray Ductile Iron Casting |

| RHG-12 | 1.30-1.35 | 20-25 | 45 | 12-14 | below zero 5-10 | Gray Ductile Iron Casting |

| RHG-16 | 1.35-1.40 | 25-30 | 50 | 16-18 | below zero 10-15 | Gray Ductile Iron Casting |

| RHG-AZ | 1.35-1.40 | 20-25 | Special for AB curing agent intelligent controller | Cast steel special | ||

| RHG-BZ | 1.15-1.20 | 10-13 | ||||

| RHG-A | 1.16-1.20 | 16-20 | Gray Ductile Iron Casting | |||

| RHG-B | 1.10-1.15 | 10-13 | ||||

AB Curing Agent Intelligent Controller

Keep the demoulding time constant: within the sand temperature 0-60 ℃, to achieve a constant mold release. Reduce head and tail sand.

The curing speed and the amount of addition are automatically adjusted according to the sand temperature and weather temperature.

Only high and low acidity sulfonic acid curing agent are needed throughout the year, which is convenient for production management.

Optimize the resin sand process: maintain the best ratio of curing agent, give full play to the effectiveness of the resin, reduce the amount of addition, improve the quality of the core, reduce casting waste, and increase economic benefits.

The addition amount of resin and curing agent, the flow rate of sand realize the screen display more intuitively.

Realize one-click conversion of resin addition amount of molding sand backing sand and surface sand, easy to operate, economical and practical, reduce resin addition amount.

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

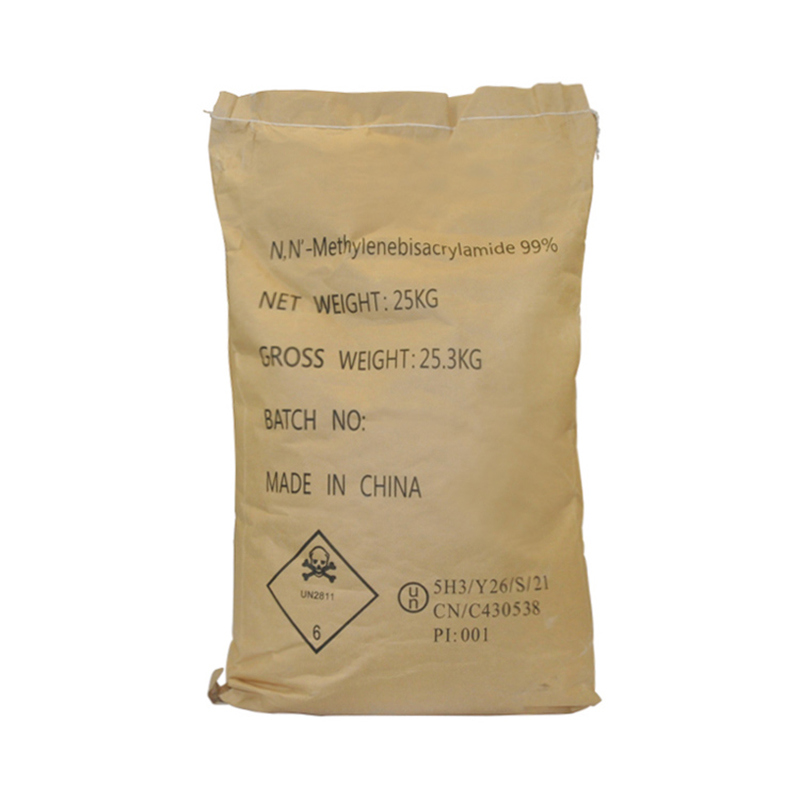

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of sincerely, good religion and high quality are the base of enterprise development, we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for Factory Cheap Hot Self-Hardening Furan Resin - Sulfonic Acid Curing Agent for Self-hardening Furan Resin – Crownchem , The product will supply to all over the world, such as: Netherlands, Amman, Hyderabad, We'll initiate the second phase of our development strategy. Our company regards reasonable prices, efficient production time and good after-sales service as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!